SERVICES

WELCOME TO ARO SA

We offer a wide range of Services for Production and Quality Control

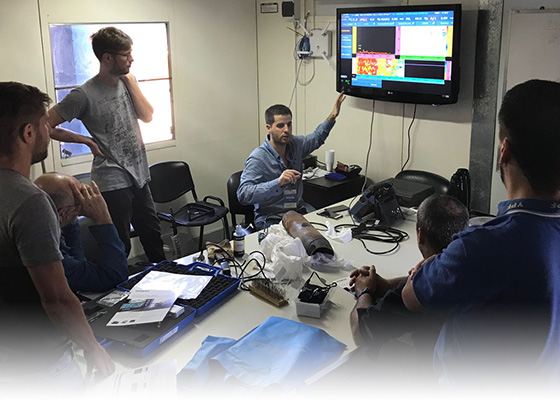

Commissioning, training and coaching

Repairs at our facilities and on site

Verification and calibration

Ultrasound and Phased Array Equipment

Profile Projectors

microscopes

Universal Testing Machines up to 100 Tn

Nuclear Density Meters

Predictive maintenance in Spectrometry

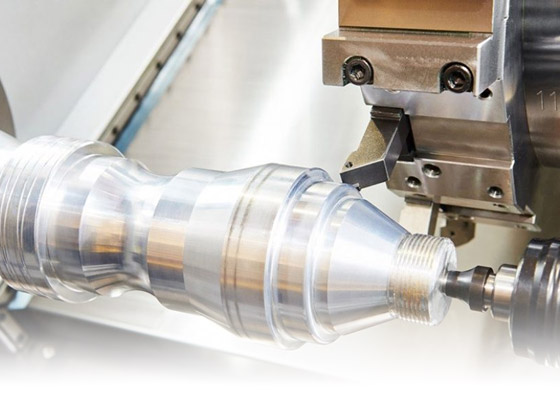

Verification of machines, CNC and EDM tools

retrofitted

Coordinate Measuring Machine

An exhaustive verification of the mechanics and electronics is carried out, proceeding to the replacement of all the electronic components (controller, servodrivers, joystick). If necessary, the measurement rulers and/or rotary encoders are replaced by optical linear ones. The measuring head can be reused if it is in good condition, or it may require the installation of a new one. It is usually necessary to adapt a PC for the chosen measurement software. The MMC that will work as a

recently acquired.

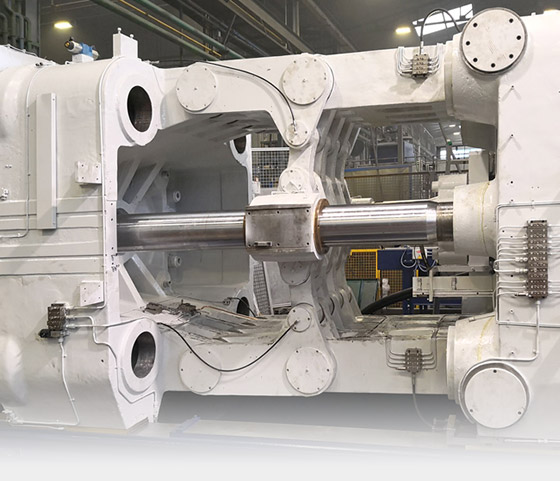

Universal Testing Machines up to 100 Tn

Retrofitting is done in Testing Machines of all brands, Static and Dynamic, Electromechanical or Hydraulic.

In all cases, the retrofit consists, after an exhaustive verification, in the change of the obsolete electronics for a new one; including software. If necessary, the load cells are changed to measure the force. In electromechanical it is possible to have to change the set of motor and driver. If they have extensometers, they are verified and calibrated; if they don't have it, it can be added. The retrofit is finished with the calibration of the equipment with our certified GOLD class INTERFACE load cells of up to 100Tn.

profile projectors

SERVICES CATALOG

Contact with our specialists

FEATURED PRODUCTS

![[:es]Medidores de espesores[:en]Thickness Gages[:]](https://arowebsite.com/wp-content/uploads/2020/05/Medidores-de-espesores-38DLP.jpg)

Ultrasonic thickness gauges

Portable equipment capable of measuring precisely and accurately in a wide variety of geometries and materials, such as carbon steel, stainless steel, polymers, composites, cast iron, forging, glass.

Scanners and crawlers for UT, Phased Array, TOFD and TFM

Semiautomatic and automatic scanners, for inspections of longitudinal, circumferential, and corrosion welding.

CUSTOMERS

BLOG

39DL PLUS: The new generation in thickness measurement

Accuracy and speed in thickness measurement are key in today's industry. With the launch of the 39DL PLUS, Evident Scientific is elevating its

Two spectrometers that will surely interest you.

Within the analytical tests, we have the spectrometers. Here we have two of them, which will surely interest you. Relevant data on spectrometers. A

What is predictive maintenance? meet him here

Predictive maintenance will anticipate possible errors. Learn more about him in this note. What is predictive maintenance and how does it work? if in

![[:es]Detectores de fallas portables[:en]Portable flaw detectors[:]](https://arowebsite.com/wp-content/uploads/2020/05/Epoch-650-web.jpg)